At C&C Charcoal, we specialize in providing high-quality, eco-friendly coconut shell charcoal briquettes that cater to different needs. Our products are designed to meet international standards, offering superior performance for both shisha and barbecue purposes

Shisha Charcoal Briquettes

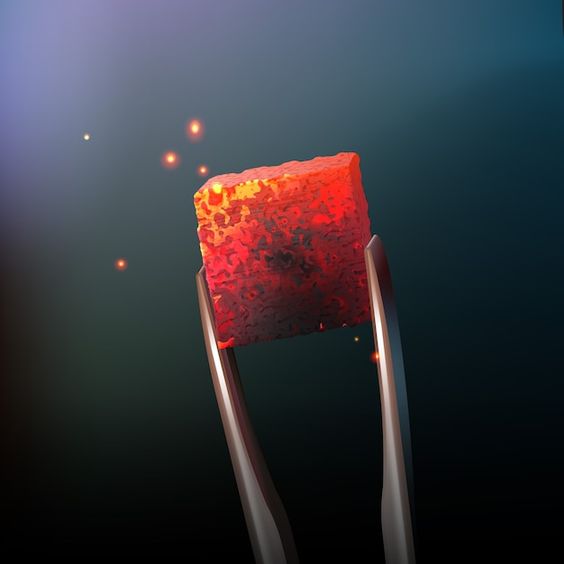

Our shisha charcoal briquettes are carefully crafted to ensure a smooth smoking experience. These briquettes are made from 100% natural coconut shells, producing no smoke, odor, or sparks, making them ideal for shisha lounges and personal use. With long burn times and high heat output, our briquettes provide the perfect balance for an enjoyable shisha session.

Barbecue Charcoal Briquettes

Our barbecue charcoal briquettes offer a consistent and long-lasting heat source, perfect for grilling and outdoor cooking. Made from sustainable coconut shells, they burn cleanly and efficiently, providing excellent heat for an extended period. Whether for a casual backyard barbecue or a professional kitchen, our briquettes deliver premium performance without harmful emissions.

Production Process

Collection of Coconut Shells

Our journey begins with sourcing the finest, naturally fallen coconut shells from sustainable coconut plantations across Sri Lanka. We work closely with local farmers to gather these shells, ensuring that the raw materials we use are not only of premium quality but also eco-friendly. By focusing on natural sourcing, we contribute to environmental conservation while maintaining the high standards of our production.

Creating Coconut Shell Dust

After collection, the coconut shells are carefully processed to create fine coconut shell dust. This dust serves as the essential raw material for our charcoal briquettes. By using cutting-edge technology, we ensure that the shells are broken down evenly, providing a consistent and smooth texture, perfect for making high-quality briquettes. The process is eco-friendly, minimizing waste while maximizing the use of every coconut shell.

Mixing the Charcoal

Once the coconut shell dust is ready, we blend it with natural, environmentally friendly binders to create the charcoal mixture. This step is crucial, as it ensures the briquettes have the strength, durability, and combustion efficiency needed for optimal performance. Our precise mixing process guarantees that every batch meets our high-quality standards, delivering superior heat and a long burn time.

Shaping and Molding

Next, the charcoal mixture is pressed into briquettes or shisha cubes using advanced machinery. Our equipment ensures that each piece is perfectly shaped and compact, providing even burning and consistent quality. We can produce briquettes and cubes in various sizes and shapes to suit the specific needs of our customers.

Final Product Ready for Market

After the shaping process, the briquettes are dried, inspected for quality, and packaged. We take pride in delivering a product that is smokeless, odorless, and spark-free. Each batch is carefully checked to ensure it meets international standards before being packed and shipped to customers worldwide. Our packaging can be customized to fit the unique requirements of different markets, ensuring convenience and efficiency in distribution.